|

|

The Endura™ Dual Split Flange (DSF) swivel joint from OPW® Engineered Systems represents the best in swivel technology. Specifically designed for the transfer of hazardous materials such as acids, solvents, petrochemicals and other toxic fluids, Endura™ sets the standard in swivel performance.

Standard Sizes: 2 in., 3 in., 4in.

Standard Materials: Carbon Steel, Stainless Steel

Standard Seals: Buna-N, Fluorocarbon, PTFE, EPDM, Neoprene

End Connections: FNPT, 150/300 ANSI Flanges, Butt Weld

End Connections: FNPT, 150/300 ANSI Flanges, Butt Weld

Benefits

Endurance – Heavy-duty construction and unique design features result in long-life, hassle-free operation

Improves Uptime Performance – Endura™ DSF swivel technology, combined with the most user-friendly counterbalance solutions,results in LESS DOWNTIME–LESS LABOR– LESS COST!

Lowest Overall Cost of Ownership – Optimized performance, downtime prevention and reduced maintenance time and costs make this the best overall loading arm solution currently available.

Features

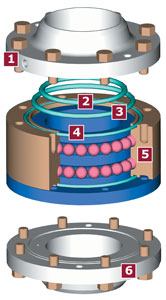

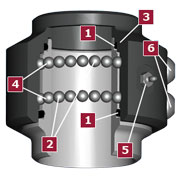

Redundant Sealing

Incorporates a main seal, back-up seal, and environmental seals

If main product seal ever leaks due to normal wear, the back-up seal contains the fluid

Any main seal leakage would be channeled to leak detection port

Environmental seal provides a third layer of protection

Bearing Module

Deep groove replaceable dual & single race ball bearing technology

Easy replacement or rebuild options

Ball removal not required to access main seals

Endura™ 8800-8900 series feature ALL stainless steel construction

Easy Maintenance

Simply unbolt sealing flanges to access seals

No ball bearings to remove

Leak Detection Port

In the event of main seal leakage, fluid would be channeled to leak detection port

Quick & easy way to monitor performance so that maintenance can be performed

Purge Port

For critical applications, an inert gas can be injected at leak detection/purge port

Inert gas pressure higher than product pressure to virtually eliminate risk of fugitive emission.

Recommended for your extreme applications!

Styles Available